]

- Chemical Free Technology

- Huge Savings on Operational Costs

- Huge Savings in Energy and Water Consumption

- Scale, Bacteria and Corrosion Control

- Longer System Lifespan

- No Discharge as drained water is re-usable for irrigation or other.

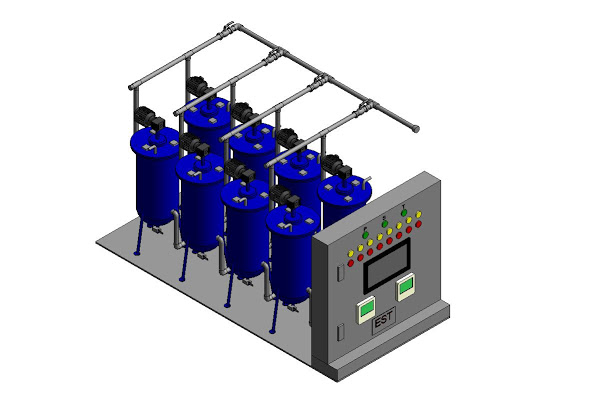

- Fully automatic, side stream installed, small foot print.

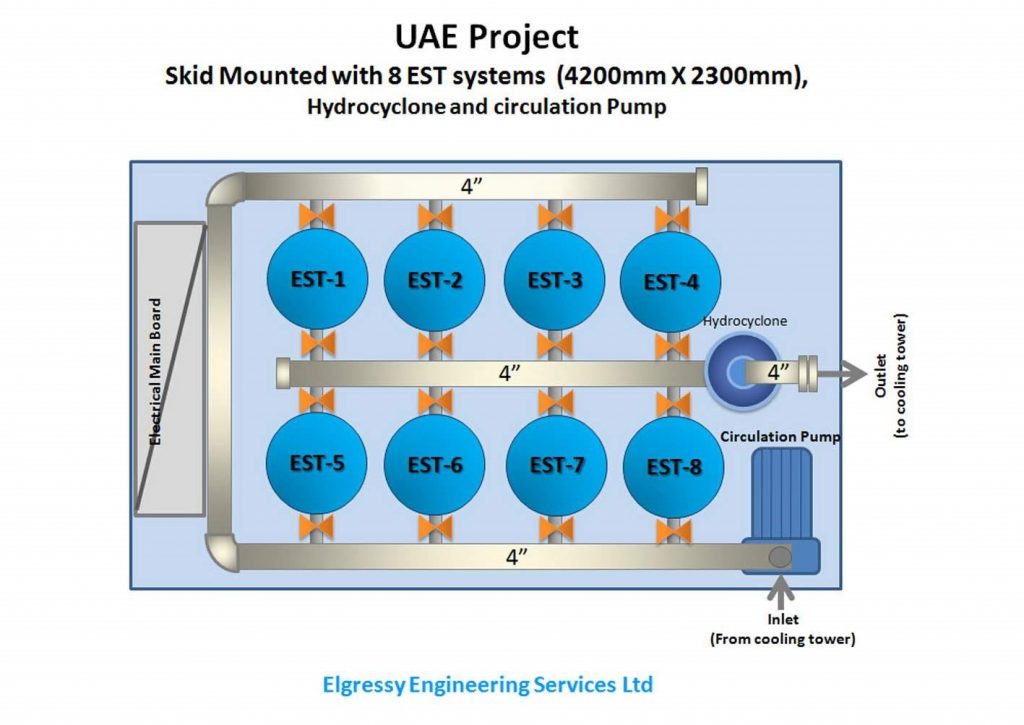

- From single EST 300 RT to MEGA EST 50.000 TR, modular.

- SCADA optional.

- Quick ROI

To learn more about EST Cooling Tower treatment Click Here

Cooling Towers Treatment – EST

EST electrochemical systems are revolutionizing cooling tower

treatment by providing a omprehensive and effective treatment against scaling, corrosion and bio-fouling.

Typically, hazardous chemicals are added to the cooling water to inhibit corrosion of system

components, to retard mineral scaling and to limit bacteria growth.

How does it work?

The EST system connects to the cooling tower basin and circulates water therein. A controlled constant DC current

is applied to the patented titanium nickel oxide anodes, generating the following efects:

Disinfection:

1. An alkaline environment of pH 13 is created next to the

reaction tank’s inner walls creating a strong disinfectant.

2. Near the anodes, 3-7% of the naturally present chlorides

are converted to free chlorine or hypochlorite (OCl-).

The OCl- level is programmable to automatically remain

at ~0.1-0.2ppm, providing additional disinfection

without the risk of corrosion.

3. Additionally, disinfecting radical oxygen, ozone and hydrogen peroxide are produced near the anode.

Scale removal:

The electrical current causes a dissociation of the salts in the water into ions, precipitating the calcium (and other cations) on the reaction tank wall. The EST is capable of precipitating > 30% calcium from the water before it crystallizes into scale, while the remaining calcium is kept

dissolved in the water.

The calcium precipitation percentage is programmable, automated and varies from

project to project.

The EST patented scraper system automatically scrapes and flushes the reaction tank to remove the precipitated scale.

Corrosion control:

The remaining Magnesium ions in the water prevent corrosion

along with controlled operation >2 MPY.

Advantages:

- Cost effective – rapid return of investment

- Solves cooling tower problems stemming from algae, corrosion and scaling

- Reduces maintenance, shut down time and labor cost

- Generates huge water savings

- Chemical free solution –eliminates the need for expensive and harmful chemicals

- Very low life cycle cost and electricity consumption

- Controllable and measurable ensuring consistent quality water

- Small footprint

- Robust and high-quality equipment with few moving parts

- Modular and simple to install or retrofit

- Proven effective in thousands of installations worldwide.

- Environmentally friendly

EST is Modular, so from 200 TR till 20.000 TR and even bigger.

Issues often found at Cooling Towers but NOT when treated with EST