ECP - Corrosion prevention

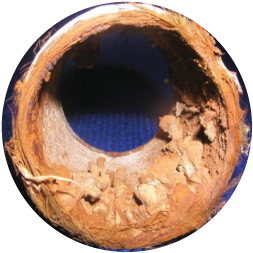

Left side Corrosion Right side Elgressy EST

Left side treatment with chemicals/Ozone

Right side United Nations Bangkok after 7 years EST treatment.

Corrosion prevention – ECP

Corrosion prevention – ECP

ECP is an effective and innovative electrolysis technology

Developed to protect the inner surfaces of hot and cold

Water pipes and tanks against corrosion and scale.

Typically, hazardous chemicals are added to the cooling water to inhibit corrosion of system

components, to retard mineral scaling and to limit bacteria growth.

The ECP is applicable for:

- Hot and cold-water systems

- Corroded and new pipes

- Copper, galvanized and combination pipe composition

- Pipes, water heaters, and tanks

Corrosion and associated scale cause major problems:

- Increased maintenance and shut down costs

- Reduced system life expectancy.

- “Red” or contaminated water that is unsuitable for human use or reuse.

Increased scale deposits which inhibit water flow and increase energy

How does it work:

- A combination of a constant direct current and a sacrificial aluminum electrode, release trace quantities of aluminum compounds into the water.

- The aluminum compounds are not easily soluble and form a homogeneous, 0.3mm thick protective layer on all internal surfaces.

- Oxygen is a contributing factor to corrosion in plastic pipes and its levels are reduced in the process.

- Specialized passages in the ECP facilitate resistance to high pressure and temperatures, even in water temperatures exceeding 60o C, when polarity reversal occurs causing corrosion by galvanization.

- This Al layer protects the system from the effects of new corrosion, prevents the spread of existing corrosion and prevents scale build-up.

Advantages:

- Cost effective – prevents pipe and water tank damage as well as pipe blockages.

- Prevention and Correction – The ECP both prevents future corrosion and works to cure the effects of corrosion already present in the system

- Versatile Operation – The system can be installed in hot and cold-water systems and is effective in water tanks and all the pipes leading in and out of the system whether galvanized, plastic or copper.

- Low operational cost – low energy use and low water consumption rates.

- Safe drinking water – no adverse effect on drinking water quality or taste.

- Simple retrofit installation – external connection to the water system, requiring no complicated installation procedures or alterations to the existing system.

- Automated – The system is fully automatic and provides continuous control over water quality.

- Environmentally friendly – free of harmful chemicals and harmless to the environment and humans.

- Rapid results – Immediate prevention of new corrosion accumulation and stoppage of “red water”.

Follow Us!